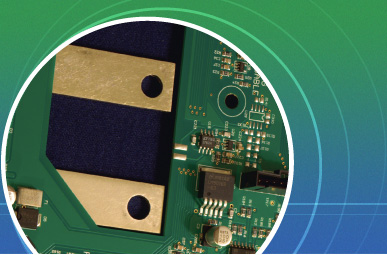

Turnkey Product Manufacturing: Prototype Services

Taking a concept from design to prototype to successful production requires a number of skills including material procurement, understanding proper assembly procedures and a passion to bring your design to fruition. The successful prototype encompasses solutions to numerous production and procurement issues that arise during design.

Group Seven’s objective is always to provide you with a product optimized for low-cost and efficient manufacturing. Our services are always tailored to your needs, and not loaded with extras that you may not want or need.

Group Seven’s professionals have developed many products from conception to prototype to production, and have extensive knowledge and experience as well as good relationships with reliable component suppliers.

Real solutions for real issues:- Prototype design suggestions that conform to IPC Workmanship Standards and are built using current ISO and IPC standards

- PCB layout service, including PCB sourcing with ISO-certified local and offshore partners

- Bill of Material (BOM) review for component RoHS-compliance and second source planning to develop a supply chain

- EMS (Electronics Manufacturing Services) partners can provide DFM (Design for Manufacturability) and DFT (Design for Test) reviews

- MRP guides the prototype component review and quotation process

At the end of the process, we can provide you with recommendations to improve manufacturing and testing, which could lead to lower production costs. We can assure you that your prototype will be optimized for production and will meet all current manufacturing standards.

If you are currently developing a prototype, please give us a call for a no-cost, no-obligation professional consultation and quote for moving your prototype into production.

- Turnkey Product Manufacturing

- About Turnkey Services

- Assembly Services

- Prototype Services

- Design Services